Ultrasonic transducer is an kind of electro-acoustic energy conversion device. It is a reversible sensor. Ultrasonic transceiver can both transmit and receive ultrasound waves. In fact, ultrasonic transmitter and receiver is the main part of sensor.

Ultrasonic vibration frequency is higher than 20khz. Its characteristics are very obvious. For example, it has high frequency, short wavelength, small bypass phenomenon, and good directionality. The ultrasound beam can travel through gases, liquids and solids. So ultrasonic transducer transmitter has wide applications, such as proximity detection, level & flow measurement, obstacle avoidance, etc.

Why choose our ultrasonic transmitter and receiver - transducer?

USSR is professional manufacturer of ultrasonic sensor transducer.

(1) More over 20 years of manufacturing experience

In 2024, we have produced transducers for exactly 20 years. We focus on the development and industrialisation of ultrasonic sensors. The factory area is more than 5000 square metres. There are a perfect production workshops, including SMT SMD, sealing, soldering wire, painting, testing and so on.

(2) Over 100 models of ultrasonic transmitter and receiver

In the beginning, our factory only produced ultrasonic transducer for reversing radar. The frequencies of these sensors are generally 40khz, 48KHz, 55.5KHz, 58KHz. They are mainly suitable for car obstacle avoidance. Later, we started to develop higher frequency ultrasoinc transceiver.

Ultra-high frequency sensors are much wider. These probes are widely used in various industries such as food machinery, agriculture, meteorology, robotics, underwater communication, etc. The main products include wind speed and direction meter transducers, level meter transducers, distance measuring sensors, flow meter transducers, obstacle avoidance transducers, fish finder transducers and so on.

(3) Strong customization ability of ultrasonic transceiver

In some occasions, we need transducers with special performance. At this time, we don't use normal ultrasonic emitter and receiver. For example, in the natural gas industry, we usually use the ultrasonic flow meters. In these flow meters, we need special ultrasonic probes. It requires that transducers need to be resistant to high temperature and high pressure.

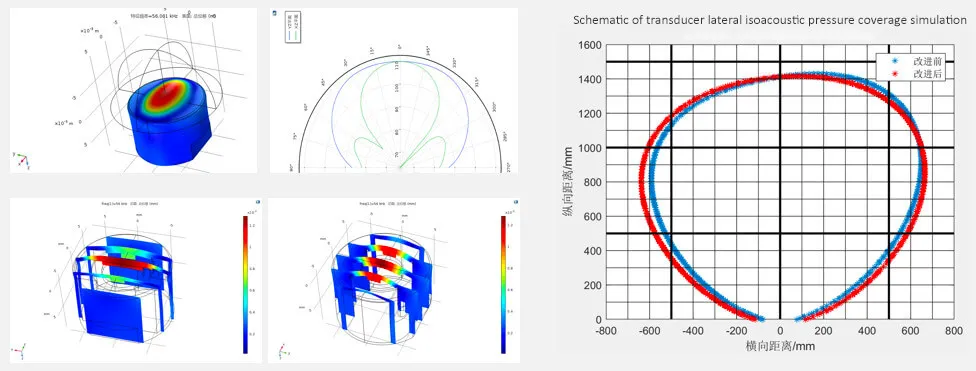

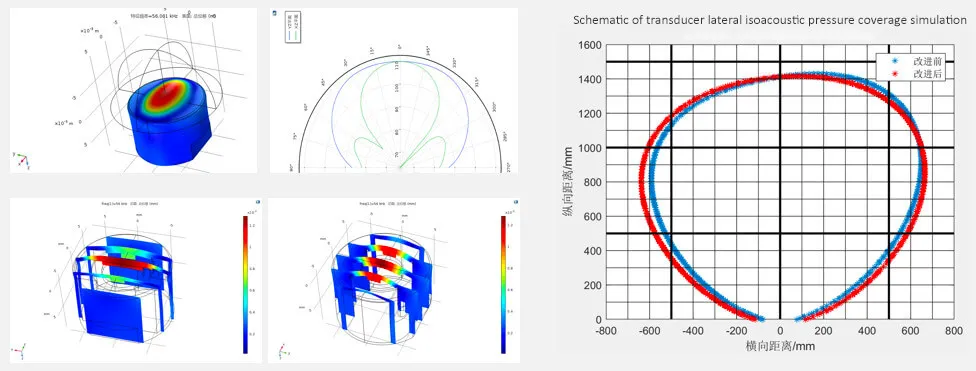

In addition, we sometimes need to use an anemometer where we are by the sea. In this case, there are requirements for the material of the sensor. It must be able to resist corrosion. For these special transducers, we are able to customize them. For a new ultrasonic transmitter and receiver, our customization day is about 25 days. Furthermore, we have the COMSOL Multiphysics platform. Therefore, we can intuitively see the various performances of the sensors when designing.

(4) Strict quality control for ultrasonic sensors

Firstly, our company has the ISO-9001:2015 and IATF 16949:2016 cerfificates. Secondly, our factory has many kinds of test equipment, such as frequency testers, oscilloscopes, aging test benches, high and low temperature test chambers, resistance testers, and so on. Rigorous tests ensure stable performance and consistency of our ultrasonic transducers.

(5) Ultrasonic transmitter and receiver circuit design

The ultrasonic transceiver cannot work alone. It needs to be with the circuit board to work. And our company have special technicians to design control boards.

Types of ultrasonic transducer transmitter

Ultrasonic transceiver come in many frequencies and shapes. We can classify ultrasonic sensors into several types.

(1) Open type and closed type ultrasonic transducer

The top of this sensor is open structure. It has high sound pressure and sensitivity. It can measure short and long distances. This transducer is not waterproof. We usually use it in indoor environment use.

But enclose type ultrasonic transmitter and receiver is the opposite. Its top surface is closed. It is usually the ultrasonic transceiver. That is, the ultrasonic emitter and receiver is all-in-one. This sensor has better waterproof ability. So we can use it outdoors.

(2) T/R, T+R ultrasonic transducer sensor

"T" means transmitter. And "R" refers to receiver. In addition, "T/R" means that there is 1pc ultrasonic transmitter and 1pc ultrasonic receiver. "T+R" means that the sensor have both transmitting and receiving functions. We usually call "T+R" the ultrasonic transceiver.

In fact, many open-top transducers are T/R types. The default closed-top transducer is a T+R type. Of course, there are exceptions.

(3) High frequency ultrasonic sensor

Here, we take the 100 KHz frequency as the dividing line. If frequency is less than 100khz, we call them high frequency sensors. Generally, the higher the frequency, the smaller the measurement distance. For example, our 100 khz ultrasonic transducer can detect objects up to 4m away. But the 1mhz ultrasonic transducer can only measure max 1 meter. Of course, these super frequency transducers are not generally used for ranging. We usually apply them for flow or oil level measurement.

(4) Waterproof and underwater ultrasonic transceiver transducer

Generally, closed-top sensors are waterproof. However, not all waterproof sensors can be suitable for underwater application. The protection class of normal enclose ultrasonic sensor is Max IP67. This does not meet the IP68 requirement for underwater applications. For example, Pool cleaning robots need the underwater ultrasonic transducers. Their function is ranging and obstacle avoidance underwater. It must be at least IP68.

How to choose a right ultrasonic transceiver (emitter & receiver)?

There are many types of ultrasonic transmitter and receivers. So we must select the right one according to our applications.

(1) Tell us your specific application

The normal application of ultrasonic transceiver is as follows: distance measurement, obstacle avoidance, or liquid level, flow rate & wind speed detection, etc. Ultrasound waves can travel through both air and water. In the two medium, the protection class requirements are different.

In addition, some gas flow meter needs special ultrasonic emitter and receiver. They must be resistant to high pressure and temperature. Besides, there are requirements for the sensor housing material. For example, some customers require stainless steel.

For ultrasonic transducer for anemometer, it often requires corrosion protection. At this time, we can use PVDF as the housing material of sensor. So you can tell us your requirements for working pressure, temperature and material, etc.

(2) Confirm the basic specifications & sizes

Firstly, you need to determine the type of ultrasonic sensor. Do you need to be "T/R" split or "T+R" integrated. For example, in the flow measurement industry, some customers need one-piece type. But other customers have want split type.

Secondly, confirm the specifications of the ultrasonic transducer, such as frequency, measuring distance, sensor size (length and diameter), etc. Actually, the frequency of transducer is different for different purposes. For example, for web guide sensor, the common frequency of ultrasonic transmitter and receiver is 200KHz, 300KHz and 400KHz. For obstacle avoidance, common frequency of ultrasonic transceiver is 40KHz, 48KHz, 55.5KHz and 58KHz. For some level & flow measurement industry, the normal frequency is 1 MHz, 2 MHz, 3 MHz, 4 MHz, 5 MHz, etc. And our ultrasonic proximity sensor usually uses the transducer of 58KHz, 75KHz, 112KHz, 200KHz, etc.

In addition, sometimes we also need to confirm the capacitance and resistance of ultrasonic transceiver. Confirmation of capacitance is to match the customer's host capacitance.

(3) Communicate requirements for key transducer performance

Some industries have special requirements for the sensor performance. You can contact us for further communication. Even in the same industry, different customers have different requirements. Let's take the ultrasonic fork sensor as an example.

For example, some customers require high temperature resistance. That is, the offset of the sensor output (e.g. 5v pressure output) should not be more than 10% at 60~90℃. Some customers have requirements for measuring range accuracy. For instance, the detection range should be up to 5mm. In addition, some companies have requirements for linearity. Of course, the most performance index of the web guide sensor transducer are residual shock and sensitivity. So must confirm the performace requirements of ultrasonic transceiver.

(4) Confirm some details of ultrasonic transmitter and receiver

① Connection type: pin or cable;

② If need cable, what's the specification & size? Is there any requirement for the cable material? For instance, some customer of high temperature gas flow meter requires that cable must be with teflon.

③ Wiring of ultrasonic transducer: connect the minus wire to transducer housing or not?

(5) Customization flow process of transducer

When you want to a custom sensor, there is at least a drawing. Of course, if you can send us the sample of your ultrasonic transmitter and receiver, it is best. Below is a brief introduction of our customization flow process.

Firstly, we will design the transducer structure;

Second, purchase raw materials for the transducer, such as cables, copper sheets, piezoelectric ceramic disc, housings, etc.

Thirdly, make samples of ultrasonic transceiver. Usually, we will make 2 samples for testing first. Verify their parameters and performance.

After testing OK, we will make other samples. Then test the sensor samples and ship out. The whole process usually takes more than 20 days.

Common applications of ultrasonic transducer transmitter

Ultrasonic transceiver has wide applications in many industries.

(1) Proximity measurement or distance measuring

We know that ultrasonic proximity sensor mainly includes the circuit board and transducer. At present, it can range up to 8 meters. They are widely used in industrial automation control. Typically, the lower the frequency, the farther the measurement distance. For example, some 40khz ultrasonic transducer can measure up to 12 meter. But 200KHz ultrasonic transmitter and receiver can only detect up to 2 meters.

Some height gauges use the ultrasonic emitter and receiver to measure kids height. In fact, ultrasonic obstacle avoidance is also the distance measuring principle. Many AGV robots and drone use ultrasonic transducer for obstacle avoidance. The same applies to automotive reversing radar. So does human presence motion detection.

(2) Level measurement for liquid & bulk material

Transceiver is one of the main components of ultrasonic level transmitter. We can use it to measure the water tank level. It sends out ultrasonic waves through the transducer. Then sense the echo. The transceiver calculates the time difference. Finally, converts it into information related to the liquid level.

Besides, we can use it as a fuel tank monitor. It can help us to detect oil leaks or oil theft. Ultrasonic transmitter and receiver is suitable for acid, alkali, corrosive liquids. But the sensor is not applicable for highly volatile liquids.

In addition, usually apply it to monitor the level of bulk materials, such as feeds, grains, coffee beans and other particles. Different measuring distances are available.

(3) Ultrasonic transducer for flow measurement

Most commonly, it uses the the time-difference method to measure flow. It can detect both air medium and liquid medium. For example, we can use it to gas flow meter and heat meter. In the medical & pharmaceutical sector, it can monitor instantaneous flow of chemical solution.

In addition, we usually apply the doppler flow meter to monitor the river flow rate. It also uses the same working principle.

(4) Material detection function

We mainly use this function to sweeping robots. In the sweeper, there are ultrasonic transceivers. The speed of sound and acoustic impedance are different for different materials. So we take advantage of this feature. Ultrasonic sensors can help sweeper to distinguish between different materials. Then it can selectively suck waste into the machine.

(5) Double sheet detection

In double feed detection scanner, we also use the ultrasonic transducers. These sensors can help to achieve paper overlapping detection. So it can avoid paper jams.

In addition, ultrasonic transmitter and receiver can used to produce double sheet sensor. It can detect papers, silicon wafers and many metal sheets.

(6) Ultrasonic transmitter and receiver for web edge guiding

It adopts the principle of linear propagation of high-frequency ultrasound waves. We use it to detect the edge position of the web material. Ultrasonic sensor is different from photoelectric sensor. It will not be affected by the transparency of the material. So there is no need to adjust when using it. It's very convenient.

The sensor is suitable for edge chasing application of impermeable materials, such as plastic film, paper, and so on. However, breathable materials such as cloth, non-woven are not applicable.

How does an ultrasonic transducer (transmitter and receiver) work?

Firstly, we can learn the structure of the transducer. Then introduce the three working modes of the ultrasonic sensor. Finally explain the working principle of the ultrasonic transducer.

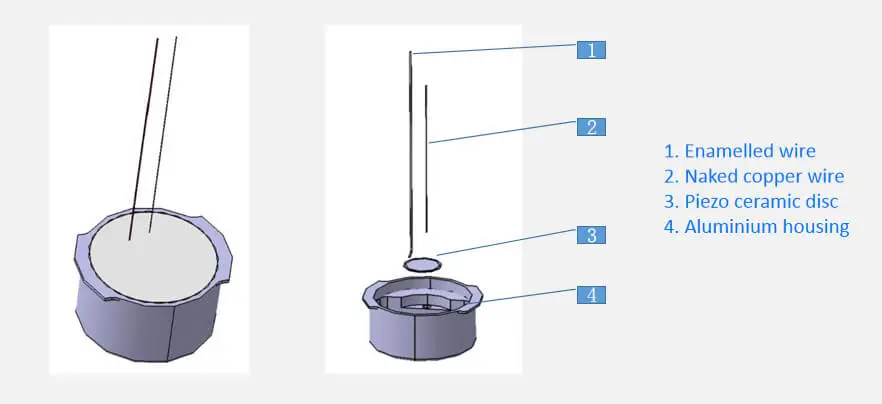

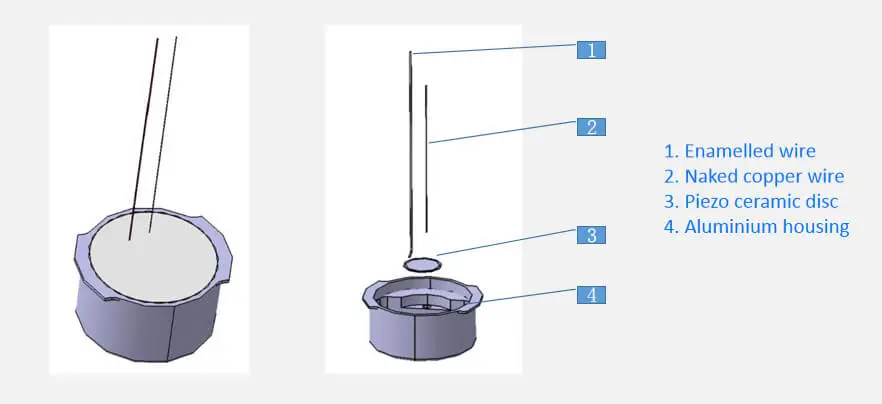

(1) Transducer structure

The diagram above shows the structure of our 55.5khz ultrasonic transceiver. This sensor consists of 4 components, namely housing, piezo ceramic disc and wires. In fact, some ultrasonic transmitter and receiver also have a matching layer on the top. PZT disc and matching layer have a direct effect on transducer performance.

(2) Three working modes of ultrasonic emitter and receiver

The working modes of transducer has three types. That is, thru-beam, reflective and separate reflective.

Through-beam mode: suitable for double sheet sensor, automatic door, anti-theft alarm, etc;

Separate Reflective mode: suitable for presence motion detection, rodent repellent, etc;

Reflective mode: suitable for distance measuring, liquid level or material level measurement. In addition, it is also suitable for material flaw detection, thickness measurement or medical scanning imaging.

(3) Working principle of ultrasonic transducer

Firstly, the pulse signal is fed from the leads to the transducer. These signals excite the transducer. It causes the piezoelectric ceramic disc to vibrate mechanically. The vibration frequency is typically above 20 KHz. As a result, ultrasonic waves are generated.

The transmitter emits ultrasound and then encounters an obstacle. These ultrasound waves are immediately reflected back. Afterwards, the receiver picks up these emitted back ultrasonic signals.

Then transducer converts these signals. Turn ultrasonic waves into weak electrical oscillations. And amplifies the signals. Eventually a control signal will be obtained. We use these signals to control various measurement and self-control circuits.

The resonant frequency at the ultrasonic transmitter should match the resonant frequency at the receiver.

Advantages and disadvantages of ultrasonic transducer transmitter

Ultrasonic sensors have advantages that infrared sensors cannot match. However, it is also not suitable for all applications.

(1) Advantages

① Strong resistance to environmental interference: it is not affected by light, transparency, colour, smoke and material.

② Wide application: it can meet most of the non-contact detection needs.

③ Higher accuracy in some applications: it has higher accuracy in measuring thickness and distance to flat surfaces;

④ Penetrating: we can use the ultrasonic sensor to detect double sheets;

(2) Disadvantages

① Ultrasonic transceiver cannot work in a vacuum. Because ultrasonic waves can not travel in a vacuum.

② Detection accuracy is affected by soft materials. Very soft fabric will absorb the sound wave. Ultimately, it is difficult for the ultrasonic transmitter and receiver to detect the target.

③ Fine objects are difficult to reflect sound waves. Not enough sound waves can be reflected back to the sensor.

④ Temperature changes of 5-10℃ or more will affect the sensing accuracy.

FAQ