This oil gauge uses the high frequency ultrasonic detection technology. So it can realize non-contact level measurement of fuel and liquid in tanks. We can adopt the installation method of external sticking. There is no drawing holes. Stick to the middle position of the bottom of diesel tank. Use ultrasonic probe to detect the oil level height. Then the built-in programme will processes the fuel level height signal intelligently. Afterwards, send the oil level information to the system platform through GPS. Finally, it will generate the fuel level report.

Specifications of external ultrasonic fuel tank level sensor:

| Parameter |

Specification |

Unit |

Notes |

| Input Voltage |

5V DC |

9V ~36V DC |

V |

Two voltages version |

| Working Current |

≤20 |

≤30 |

mA |

The higher the voltage, the smaller the current |

| Explosion-proof grade |

Exia II CT6 |

|

/ |

| Measuring Range |

46~1000 |

mm |

The 1m is the regular default range. And 2m and 3m are also available. The 2m and 3m are usually suitable for construction machinery. |

| Sensor Model |

uols01 |

|

Oil level sensor thickness is 18 mm. It's suitable for iron and aluminium tanks. But it's not suitable for plastic tanks. |

| uols02 |

|

The sensor thickness is 6mm. It is suitable for iron, aluminium and plastic tanks. If the vehicle chassis is very low , you can choose this model. |

| uols03 |

|

The sensor thickness is 13mm. Suitable for iron, aluminum and plastic fuel tanks. This model is more versatile than the two models above. |

| Measurement Accuracy |

≤0.5%FS |

|

/ |

| Resolution Ratio |

0.1 |

mm |

/ |

| Measuring Angles |

0~5 |

° |

The horizontal inclination angle must be less than 5 degrees. Otherwise, we can't install the ultrasonic fuel gauge successfully. |

| The Wall Thickness of the Tank for Test |

0.6~5.0 |

mm |

Blind zone 5cm |

| 5.0~10.0 |

mm |

Blind zone 10 cm |

| ≥10.0 |

mm |

Set the blind parameters according to specific wall thickness |

| Interface |

RS232 / RS485/0-5V/4-20mA |

|

If transmission distance is greater than 10m, please select RS485 |

| Communication Rate |

9600 |

bit/S |

Baud rate is adjustable |

| Working Temperature |

-40 ~75 |

℃ |

/ |

| Storage temperature |

-45 ~80 |

℃ |

/ |

| With GPS Tracker and APP or not |

Yes. Our ultrasonic fuel tank level sensor is with GPS tracker and phone APP. |

| Line Sequence Definition |

Black - ground wire; Red - positive pole; Yellow TX/B; Green RX/A |

Remarks:

(1) Long-term stock models are RS232 and RS485 fuel level sensors. If you need 0~5V or 4~20mA, delivery time is 15 days.

(2) Sensors are suitable for all metal tanks, such as iron, aluminium, stainless steel, copper, etc.

Features of our ultrasound oil tank gauge:

Ultrasonic diesel tank level sensor is different from traditional liquid level detection devices. It has high measurement accuracy. Moreover, it is easy to use. We can install the sensor externally, so it does not damage the diesel tank. In addition, we can connect the GPS tracker and APP to achieve remote monitoring of oil level.

Ultrasonic fuel gauge can adapt to complex road conditions. It can also monitor the real-time oil level of special tank vehicles. And also can output stable data on the tank level of dangerous goods transport vehicles.

① Waterproof and lightweight structure design. External installation with no drawing holes;

② GPS and APP online monitoring of fuel data. So it can help companies with fleet fuel management.

③ There are wo bracket fixing solutions. So it's suitable for installation in various vehicles models;

④ DC 5V and 9~36V power supply;

⑤ Four communication interfaces for choice: RS232/RS485/current and voltage analogue;

⑥ 2MHz ultrasonic frequency. Super signal strength. So it can adapt to different materials of oil tanks;

⑦ The sensor has built-in anti-interference structure and circuit. Because of intelligent algorithm filtering, the output has high stability;

⑧ Three sensing ranges are selectable. The default is 1 meter. And 2m and 3m are available. Therefore, it can meet the needs of different size tanks.

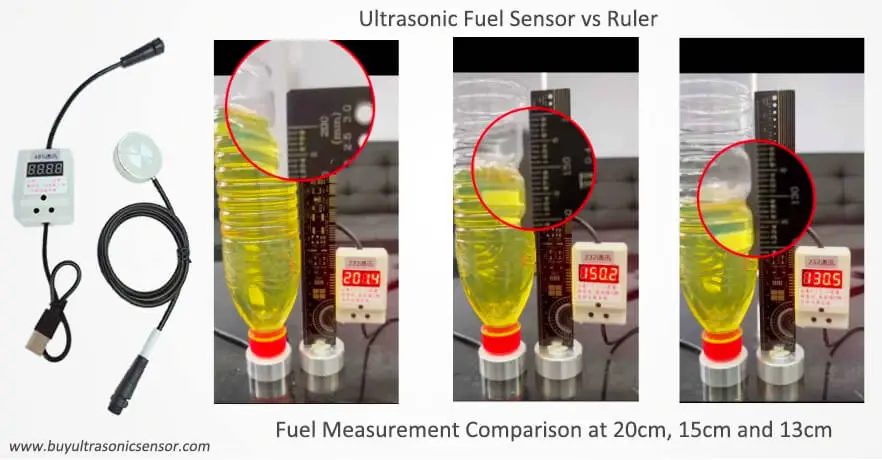

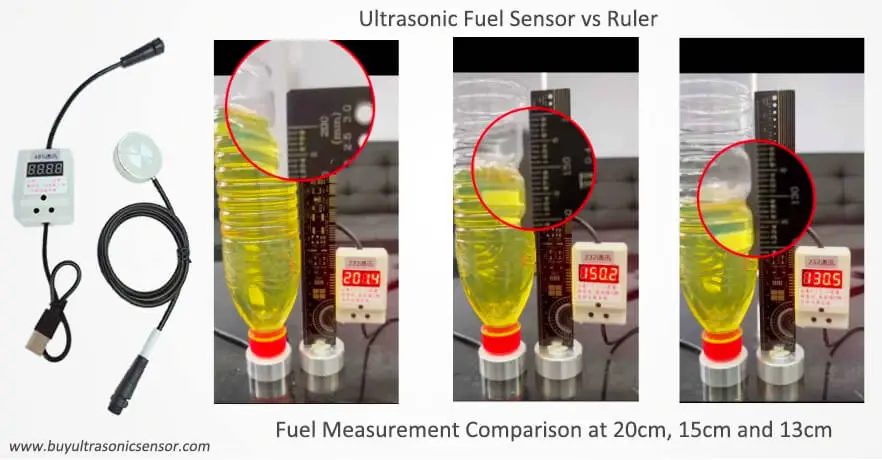

⑨ Our diesel tank level monitor has high measurement accuracy. It is with built-in high-precision calculation model. The measurement resolution reaches millimetre level. You can measure it with a ruler and a fuel level sensor as the below picture. Then compare two data. You will find that the oil level error is very small.

Besides, the refuelling error is also very small. Our customer has specially tested the refuelling data. The error is as follows: 288-288.64=-0.64L.

Function Introduction of Our Fuel Consumption Monitoring Platform

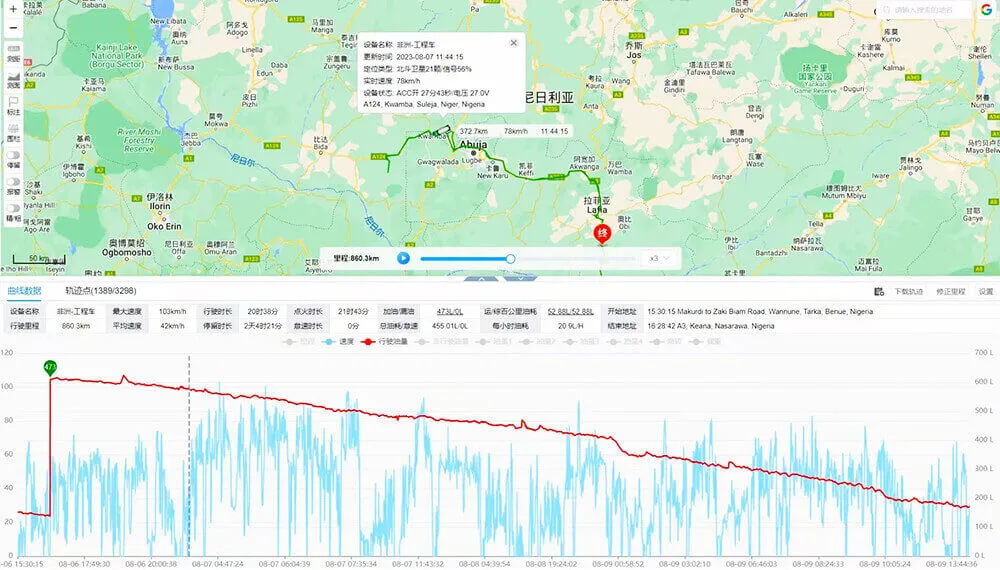

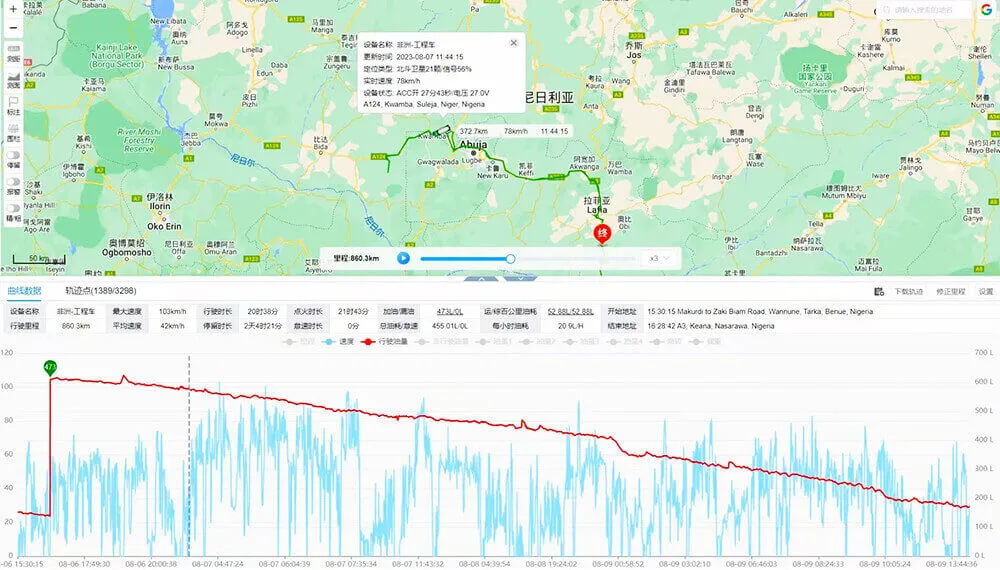

Use the ultrasonic fuel level sensor with the IoT terminal. Transmit the fuel level value to the monitoring platform in real time. Or display it directly on the local display. The platform can display rich oil data.

Moreover, it support the following data statistics, such as 100 km fuel consumption, working hours fuel consumption, time fuel consumption, mileage fuel consumption. And the plateform also shows the fueling and oil leakage data. In addition, it can provide various reports such as monthly overview report, daily overview report, monthly detail report and functional trend report. So it's convenient for fuel management data control. The GPS tracker can also manage vehicle location in real time.

Advantages of the diesel consumption platform:

① Rapid deployment of the custom platform interface and domain name;

② Accurate fuel level data and rich analysis reports;

③ Supports four-channel oil level reading in the reservoir;

④ Adapt to mainstream video and non-video vehicle play system;

⑤ Quick refueling and oil leakage alarm push;

⑥ Chinese and English interface, supports overseas deployment;

⑦ Original refueling calibration algorithm and accurate fuel volume. It an achieving a single refueling calibration error of less than ±3%. Besides, we can solve the calibration problem of special shaped fuel tanks.

How the platform monitors fuel consumption?

① Firstly, report the data

The ultrasonic diesel tank level sensor measures the data. Then vehicle terminal uploads these data to the cloud platform through the 2G/4G network.

② Secondly, the cloud platform receives the reported data.

These data include: vehicle information, GPS terminal information, reporting time, fuel level data and location information, etc.

③ Thirdly, generate client fuel volume data

Generate fuel quantity and fuel consumption reports. We can view these data on computer or phone APP.

④ Fourthly, check the refueling amount

We can compare the fuel volume data. That is, the refueling volume at the gas station and the refueling volume on the platform. See if there is a significant difference between the two data. This can prevent gas stations from falsifying the amount of fuel.

Appliation ranges of ultrasonic fuel gauge:

(1) Applicable oil tank materials: any metal cans and plastic tanks. Note: uols01 is not suitable for plastic tanks.

(2) Diesel tank level measurement range: Normally 1 meter. And 2-meter and 3-meter ranges are custom.

(3) Fuel tank wall thickness: Regular wall thickness is 0.6~5.0mm. Also suitable for 5.0~10.0 thickness tank. If your tank wall thickness exceeds 10mm, please contact us.

(4) Applicable liquids: diesel and gasoline. If measuring water or other liquid levels, please contact us.

(5) Applicable tanks and vehicles: logistics vehicles, transportation trucks, engineering vehicles (dump / muck / mixer trucks), construction machinery (excavators, bulldozers), sanitation trucks, garbage trucks, mining trucks, tractors, box cars, trailers, containers, generator, etc.

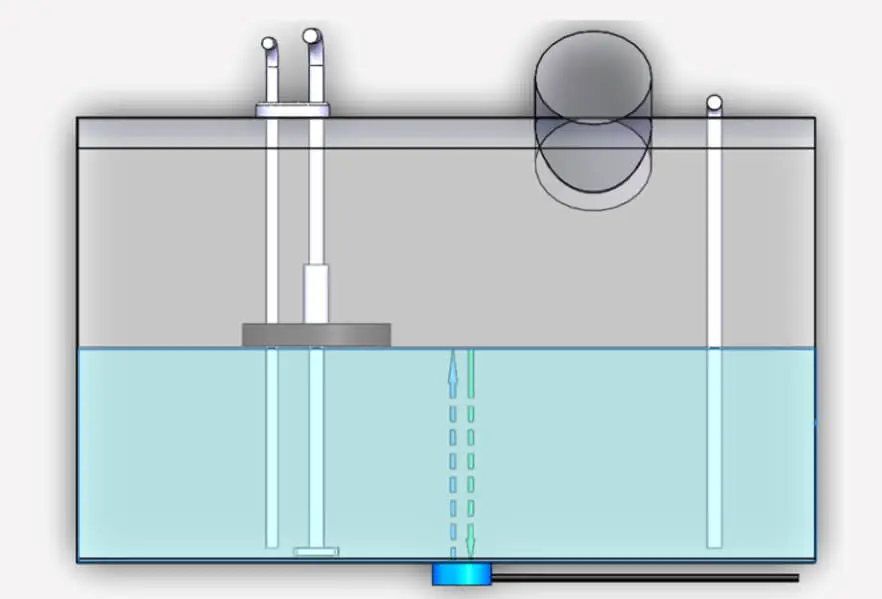

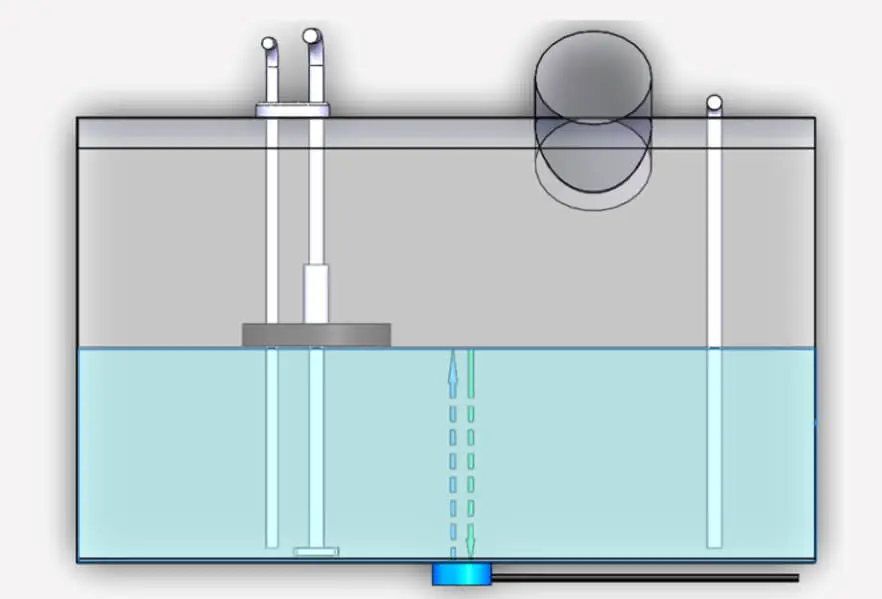

How does ultrasonic fuel tank level sensor work?

The frequency of our oil level sensor is 2MHz. High frequency ultrasound has obvious characteristics. That is, it has good directionality, strong penetrating power, and long propagation distance. So it is widely used for liquid & fuel level measurement.

Ultrasonic probe generates ultrasonic signals. The signal will pass through the container wall (i.e. the tank wall). Propagation continues in the liquid in the container (tank). Ultrasonic waves reach the interface between two different medium, such as diesel and air. It will reflect. The ultrasonic signal is returned to the diesel tank level sensor. Therefore, it can calculate the liquid level according to the time and speed. (Note: Obstacles will cause the ultrasonic signal to return early. So please avoid them).

This is the principle of echo ranging. Install the sensor on the outside of the bottom of the tank. An external power source can drive the piezo ceramic chip in the oil level sensor. It emits mechanical waves. At the same time, receives mechanical waves. Finally, we measure the fuel level using the time difference of mechanical waves.

We can simply describe the process of its working principle as: emitting ultrasonic signal → signal propagates in the medium → encounters oil surface reflection → receives reflected signal → calculates distance.

Why we need the external ultrasonic oil level monitor?

Below we will compare the three main fuel consumption sensors. Namely, capacitive, submersible, and external ultrasonic diesel level sensor.

| Fuel Consumpation Sensor |

Capacitive Fuel Level Sensor |

Submersible Liquid Pressure Oil Level Sensor |

External Ultrasonic Fuel Tank Level Sensor |

| Price |

A bit more expensive than ultrasonic type |

Cheapest |

Affordable |

| Working Principle |

Monitor the changes in capacitance between probe and tank |

Based on proportionality between the hydrostatic pressure of diesel and the height |

Calculate the time difference between transmitting and receiving ultrasonic waves |

| Installation |

Installation after drilling holes in the top of the diesel tank |

Install the sensor probes through the fuel filling port |

External mounting on the bottom of the tank. No drilling. |

| Application |

All types of vehicles and tanker trucks |

Static fuel tanks, storage tanks and some vehicles |

Various vehicle fuel tanks and tank trucks |

| Measurement Accuracy |

99%~99.5% |

98%~99% |

99%~99.7% |

| Built-in Algorithm |

With advanced filtering algorithm |

No. Unable to filter interference signals |

Yes. It can filter interference signals |

| Advantage |

High precision, wide applicability;

And not affected by tank material and wall thickness;

With GPS, APP and fuel consumption monitor platform |

Cheap and wide applicability; |

No drawing hole, high precision, high sensitivity, easy installation;

Also with GPS, APP and oil consumption monitor platform |

| Disadvantage |

It needs to drill hole on the tank. Installation is a little more troublesome. |

Data accuracy is slightly worse |

The measurement is affected by tank material sizes, and wall thickness. |

From the above table, we can see that ultrasonic sensors have various advantages. It can meet most vehicle oil level measurement needs. Moreover, it can bring many benefits to fleet management. We will analyse this in the following.

Advantages of ultrasound diesel tank level sensor for fleet management

We can apply the sensors to various vehicles, such as logistics vehicles, large trucks, buses, mixer trucks, etc. Digitally record vehicle refueling and fuel consumption. Prevent oil theft from occurring. So avoid wasting resources. At the same time, improve operational efficiency and traffic safety. Finally, it can strengthen the level of fleet operation and management.

(1) Prevent oil theft

This is more than just a diesel tank level sensor. It is a GPS fuel level monitoring system. The system includes the sensor, GPS tracker, APP and monitor platform. It can realize 24-hour monitoring of vehicle fuel consumption. When oil theft or oil leakage occurs, there will be records on the platform. Moreover, the mobile APP will also receive oil leakage alarm reminders.So it can effectively prevent oil theft from happening.

(2) Optimize operating costs

The monitoring platform can count the fuel volume and mileage at any time. And calculate the fuel consumption per kilometer. Therefore, managers analyze transportation routes that are economical and fast.

(3) Optimize driver driving behavior

Real-time monitoring of fuel volume data. It can effectively improve drivers’ driving habits. Reduce normal fuel consumption.

(4) Strengthen operational management

GPS fuel sensor helps monitor vehicle fuel consumption changes. And generate oil volume change report or curve chart. These data are displayed on the user's computer or mobile APP. It can intuitively reflect the normal and abnormal consumption of oil. Achieve high-level management of fuel consumption.

How to install & mount the ultrasonic fuel tank level sensor?